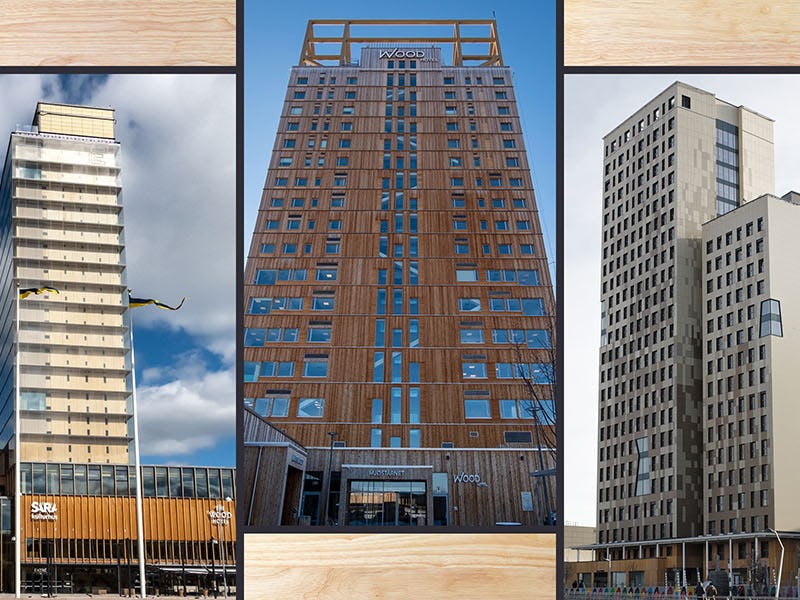

Is This Sustainable, Entirely Wood Skyscraper the Future of Cities?

Wood engineered for strength and safety offers architects an alternative to carbon-intensive steel and concrete.

At the University of Toronto, just across the street from the football stadium, workers are putting up a 14-story building with space for classrooms and faculty offices. What’s unusual is how they’re building it — by bolting together giant beams, columns, and panels made of manufactured slabs of wood.

As each wood element is delivered by a flatbed, a tall crane lifts it into place and holds it in position while workers attach it with metal connectors. In its half-finished state, the building resembles flat-pack furniture in the process of being assembled.

The tower uses a new technology called mass timber. In this kind of construction, massive, manufactured wood elements that can extend more than half the length of a football field replace steel beams and concrete. Though still relatively uncommon, it is growing in popularity and beginning to pop up in skylines around the world.

Today, the tallest mass timber building is the 25-story Ascent skyscraper in Milwaukee, completed in 2022. As of that year, there were 84 mass timber buildings eight stories or higher either built or under construction worldwide, with another 55 proposed. Seventy percent of the existing and future buildings were in Europe, about 20 percent in North America, and the rest in Australia and Asia, according to a report from the Council on Tall Buildings and Urban Habitat. When you include smaller buildings, at least 1,700 mass timber buildings had been constructed in the United States alone as of 2023.

Mass timber is an appealing alternative to energy-intensive concrete and steel, which together account for almost 15 percent of global carbon dioxide emissions. Though experts are still debating mass timber’s role in fighting climate change, many are betting it’s better for the environment than current approaches to construction. It relies on wood, after all, a renewable resource.

Mass timber also offers a different aesthetic that can make a building feel special. “People get sick and tired of steel and concrete,” says Ted Kesik, a building scientist at the University of Toronto’s Mass Timber Institute, which promotes mass timber research and development. With its warm, soothing appearance and natural variations, timber can be more visually pleasing. “People actually enjoy looking at wood.”

Same wood, a stronger structure

Using wood for big buildings isn’t new, of course. Industrialization in the 18th and 19th centuries led to a demand for large factories and warehouses, which were often “brick and beam” construction — a frame of heavy wooden beams supporting exterior brick walls.

As buildings became ever taller, though, builders turned to concrete and steel for support. Wood construction became mostly limited to houses and other small buildings made from the standard-sized “dimensional” lumber you see stacked at Home Depot.

But about 30 years ago, builders in Germany and Austria began experimenting with techniques for making massive wood elements out of this readily available lumber. They used nails, dowels, and glue to combine smaller pieces of wood into big, strong, and solid masses that don’t require cutting down large old-growth trees.

Engineers, including Julius Natterer, a German engineer based in Switzerland, pioneered new methods for building with the materials. Architects, including Austria’s Hermann Kaufmann, began gaining attention for mass timber projects, including the Ölzbündt apartments in Austria, completed in 1997, and Brock Commons, an 18-story student residence at the University of British Columbia, completed in 2017.

In principle, mass timber is like plywood but on a much larger scale: The smaller pieces are layered and glued together under pressure in large specialized presses. Today beams up to 50 meters long, usually made of what’s called glue-laminated timber, or glulam, can replace steel elements. Panels up to 50 centimeters thick, typically cross-laminated timber, or CLT, replace concrete for walls and floors.

These wood composites can be surprisingly strong — stronger than steel by weight. However, a mass timber element must be bulkier to achieve that same strength. As a building gets higher, the wooden supports must get thicker; at some point, they simply take up too much space. So, for taller mass timber buildings, including the Ascent skyscraper, architects often use a combination of wood, steel, and concrete.

Historically, one of the most obvious concerns with using mass timber for tall buildings was fire safety. Until recently, many building codes limited wood construction to low-rise buildings.

Though they don’t have to be completely fireproof, buildings need to resist collapse long enough to give firefighters a chance to bring the flames under control and for occupants to get out. Materials used in conventional skyscrapers, for instance, are required to maintain their integrity in a fire for three hours or more.

To demonstrate mass timber’s fire resistance, engineers put the wood elements in gas-fired chambers and monitor their integrity. Other tests set fire to mock-ups of mass timber buildings and record the results.

These tests have gradually convinced regulators and customers that mass timber can resist burning long enough to be fire-safe. That’s partly because a layer of char tends to form early on the outside of the timber, insulating the interior from much of the fire’s heat.

Mass timber got a major stamp of approval in 2021 when the International Code Council changed the International Building Code, which serves as a model for jurisdictions around the world, to allow mass timber construction up to 18 stories tall. With this change, more and more localities are expected to update their codes to routinely allow tall, mass timber buildings rather than requiring them to get special approvals.

There are other challenges, though. “Moisture is the real problem, not fire,” says Steffen Lehmann, an architect and scholar of urban sustainability at the University of Nevada, Las Vegas.

All buildings must control moisture, but it’s absolutely crucial for mass timber. Wet wood is vulnerable to deterioration from fungus and insects like termites. Builders are careful to prevent the wood from getting wet during transportation and construction, and they deploy a comprehensive moisture management plan, including designing heat and ventilation systems to keep moisture from accumulating. For extra protection from insects, wood can be treated with chemical pesticides or surrounded by mesh or other physical barriers where it meets the ground.

Another problem is acoustics since wood transmits sound so well. Designers use sound insulation materials, leave space between walls, and install raised floors, among other methods.

Potential upsides of mass timber

Combating global warming means reducing greenhouse gas emissions from the building sector, which is responsible for 39 percent of emissions globally. Diana Ürge-Vorsatz, an environmental scientist at the Central European University in Vienna, says mass timber and other bio-based materials could be an important part of that effort.

In a 2020 paper in the Annual Review of Environment and Resources, she and colleagues cite an estimate from the lumber industry that the 18-story Brock Commons in British Columbia avoided the equivalent of 2,432 metric tons of CO2 emissions compared with a similar building of concrete and steel. Of those savings, 679 tons came from the fact that less greenhouse gas emissions are generated in the manufacture of wood versus concrete and steel. Another 1,753 metric tons of CO2 equivalent were locked away in the building’s wood.

“If you use bio-based material, we have a double win,” Ürge-Vorsatz says.

However, a lot of the current enthusiasm for mass timber’s climate benefits is based on some big assumptions. The accounting often assumes, for instance, that any wood used in a mass timber building will be replaced by the growth of new trees and that those new trees will take the same amount of CO2 out of the atmosphere over time. However, if old-growth trees are replaced with new tree plantations, the new trees may never reach the same size as the original trees, some environmental groups argue. There are also concerns that increasing demand for wood could lead to more deforestation and less land for food production.

Studies also tend to assume that once the wood is in a building, the carbon is locked up for good. But not all the wood from a felled tree ends up in the finished product. Branches, roots, and lumber mill waste may decompose or get burned. And when the building is torn down, if the wood ends up in a landfill, the carbon can find its way out in the form of methane and other emissions.

“A lot of architects are scratching their heads,” says Stephanie Carlisle, an architect and environmental researcher at the nonprofit Carbon Leadership Forum, wondering whether mass timber always has a net benefit. “Is that real?” She believes climate benefits do exist. However, she says understanding the extent of those benefits will require more research.

In the meantime, mass timber is at the forefront of a whole different model of construction called integrated design. In traditional construction, an architect designs a building first, and then multiple firms are hired to handle different parts of the construction, from laying the foundation to building the frame, installing the ventilation system, and so on.

In integrated design, says Kesik, the design phase is much more detailed and involves the various firms from the beginning. The way different components will fit and work together is figured out in advance. The exact sizes and shapes of elements are predetermined, and holes can even be pre-drilled for attachment points. That means many of the components can be manufactured off-site, often with advanced computer-controlled machinery.

A lot of architects like this because it gives them more control over the building elements. And because so much of the work is done in advance, the buildings tend to go up faster on-site — up to 40 percent faster than other buildings, Lehmann says.

Mass timber buildings tend to be manufactured more like automobiles, Kesik says, with all the separate pieces shipped to a final location for assembly. “When the mass timber building shows up on-site, it’s really just like an oversized piece of Ikea furniture,” he says. “Everything sort of goes together.”

This article originally appeared in Knowable Magazine, an independent journalistic endeavor from Annual Reviews. Sign up for the newsletter.