New study wants astronauts to use their pee to build a lunar base

Future Moon colonies might be a little stinky.

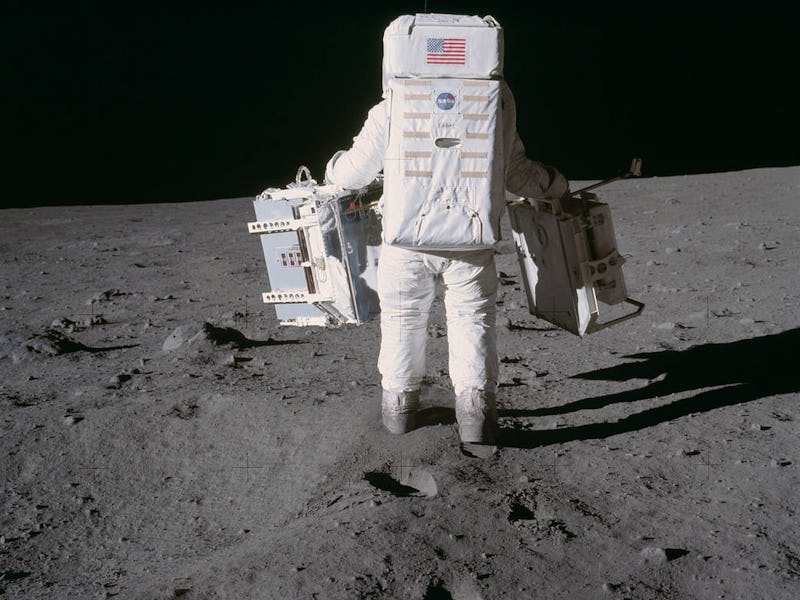

It's been more than 50 years since we first landed on the Moon, and humanity is planning a return to the lunar surface pretty soon with NASA's upcoming Artemis mission.

As NASA has repeatedly pointed out when discussing the return to the Moon, this time the voyage will be "to stay." And in order to do that, we need to get creative.

In the quest to find sustainable solutions to build future colonies on the Moon, a group of scientists are suggesting that astronauts use what they already got– their own urine.

A study, published this week in the Journal of Cleaner Production, suggests that the main ingredient found in human urine would be ideal to create a mixture for concrete on the Moon. The research is the latest in some other equally creative ideas to help build colonies in space, mushroom houses included, in an effort to reduce the amount of resources astronauts need to bring with them on their journey to the lunar surface.

The study was carried out in collaboration with the European Space Agency.

The next time we go to the Moon, it's going to look a lot different than the Apollo mission.

The team of researchers behind the new study found that urea, an organic compound that is the second most abundant component of urine after water, could be used as a chemical admixture to make concrete on the Moon.

"With this study, we have seen that a waste product, such as the urine of the personnel who occupy the moon bases, could also be used," Ramón Pamies, a professor at the Polytechnic University of Cartagena, Murcia, and one of the authors of the new study, says in a statement.

In order to make the concrete, the urine would be mixed with lunar regolith, the layer of rocky material that covers the Moon's bedrock. The urea in the urine is capable of breaking hydrogen bonds, and can therefore reduce the viscosity of the regolith mixture, making it more moldable before it hardens into its final form, according to the study.

As a result, the use of urine would reduce the need to find other resources on the Moon such as water, or the need to carry other resources from Earth to the Moon.It costs around $10,000 to transport just about 0.45 kilograms of supplies from Earth to space, therefore transporting entire construction material would be less than ideal.

In order to test out this new method, the team of scientists used a material similar to lunar regolith, and mixed it it with urea to create different concrete cylinders using a 3D printer.

The results of the urine experiment ironically resemble another form of human waste.

The researchers are still not sure whether they would need to extract the urea from the urine, or use the urine as is for the concrete mixture.

"The actual water in the urine could be used for the mixture, together with that obtained on the moon, or a combination of both," Anna-Lena Kjøniksen, a researcher at the University of Norway, and one of the authors behind the new study, says in a statement.

Previous research has suggested that ancient deposits of ice can be found in the Moon's dark craters at its southern and northern poles, and water could also be used as an important resources for future astronauts on the Moon.

Abstract: When developing materials for lunar construction, it is essential to minimize the weight of components that have to be brought in from Earth. All necessary ingredients for geopolymers could potentially be sourced on the lunar surface, which is why the material might be an efficient construction material for infrastructure on the moon. Finding a chemical admixture that can be easily obtained on the moon, which can increase the workability while utilizing less water, would be highly beneficial for utilizing lunar regolith geopolymers for lunar 3D printing. Urea can break hydrogen bonds, and therefore reduces the viscosities of many aqueous mixtures. Since urea is the second most abundant component in urine (after water), it is readily available anywhere there are humans. We have therefore explored the possibility of utilizing urea as a chemical admixture for lunar geopolymers. Addition of urea has been compared with polycarboxylate and naphthalene based superplasticizers, and with a control mixture without superplasticizer. When curing the sample containing urea at 80 °C, the initial setting time became longer. The samples containing urea or naphthalene-based superplasticizers could bear heavy weights shortly after mixing, while keeping an almost stable shape. Samples without superplasticizer or containing the polycarboxylate-based admixture were too stiff for mold-shaped formation after casting. Samples containing urea and naphthalene-based admixtures could be used to build up a structure without any noticeable deformation. Initial compressive strength of the samples with urea was higher than for the two other specimens containing superplasticizers, and it continued to rise even after 8 freeze-thaw cycles. Microstructural studies revealed that superplasticizers can influence the formation of additional air voids within the samples.