Robot fabric could solve the most annoying part of camping

It's time to expand our idea of what fabric can do, a new Yale study says.

Throughout human history, fabrics have been at the forefront of innovation. From hand weaving to looms to sewing machines, the cloth we depend on for so much has become stronger, more flexible, and a symbol of human ingenuity.

Now, a team from Yale has developed what could be the next evolution: a standalone platform for tremendously strong robotic fabrics.

The tool, detailed in a study published in the Proceedings of the National Academy of Sciences this week, creates fabrics that are “thin, lightweight, and breathable,” and also “harness complex curvature and limitless surface configurations as key functions.”

In other words, they can fold themselves.

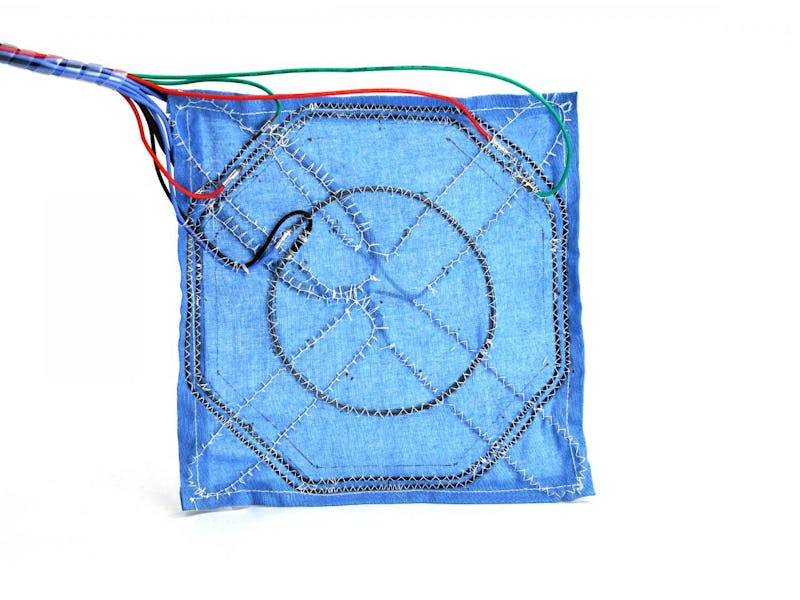

A top-down view of the robotic fabric.

The study authors use a fiber-like material called Nitinol SMA wire, which can remember its shape and return to its original formation “even after multiple distortions when heated above a critical temperature,” according to its commercial sellers.

The team was able to anchor the Nitinol SMA wire to fabric through a technique called “couching,” which has been used in sewing since the Middle Ages, most notably in the Bayeux Tapestry of the early 1100s.

The Bayuex Tapestry, created in the early 1100s. Scientists used some of the same techniques that were used to create the ancient story.

The SMA wire presented some challenges, twisting at times when the scientists were trying to make it bend. To get around that problem, the researchers flattened the wires into ribbons. They found that couching was able to “hold a flattened ribbon tighter to a fabric base, preventing the actuator from overturning." What was good enough for a thousand-year-old tapestry describing the conquest of England in 1066 is still good enough for cutting-edge robotics.

Getting the right material was only part of the challenge. The team also had to add sensors to the fabric to enable it to understand and react to changes in its environment. The team used a self-coagulating, conductive ink that they could print onto the fabric itself, creating what researchers describe as an “electrically conductive pathway that changes in resistance as the fabric weave is stretched.”

The robotic fabric moving into shape.

A potent example in the study of how this fabric might be used is as a robotic fabric tourniquet, able to wrap itself around a damaged circuit by contracting itself and holding a tightened clover-shaped pose.

Creating a responsive piece of fabric like this gives researchers hope that it “could potentially be used as a smart garment in military or exploratory environments.”

Showing how the fabric would turn itself into a tourniquet.

But the uses are not limited to soldiers or adventurers. Researchers say that their robotic fabric could be “a preliminary version of a self-deploying shelter or load-bearing furniture.” The usefulness of a cheap, widely available self-deploying shelter would be hard to understate. On a more basic level, it would also eliminate the need to fight with your tent every time you go camping.

But there are several steps to go before bringing this fabric to the public, including improving washability and heat dissipation. Reusability is also key for a fabric of this nature.

Ultimately, the innovation challenges our ideas of what fabric can be, but it is too soon to say if this is the Lycra of our generation.

By “treating fabric as the foundation of a robot, it can be enhanced from a passive material to smart adaptive clothing, self-deploying structures, or lightweight shape-changing machinery,” the researchers say.

Abstract: Fabrics are ubiquitous materials that have conventionally been passive assemblies of interlacing, inactive fibers. However, the recent emergence of active fibers with actuation, sensing, and structural capabilities provides the opportunity to impart robotic function into fabric substrates. Here we present an implementation of robotic fabrics by integrating functional fibers into conventional fabrics using typical textile manufacturing techniques. We introduce a set of actuating and variable-stiffness fibers, as well as printable in-fabric sensors, which allows for robotic closed-loop control of everyday fabrics while remaining lightweight and maintaining breathability. Finally, we demonstrate the utility of robotic fabrics through their application to an active wearable tourniquet, a transforming and load-bearing deployable structure, and an untethered, self-stowing airfoil.