Sneakers do shoes one better, customizing performance for athletes and flaunting some aggressive styling. They are one of the few omnipresent accessories that didn’t exist in any real form a century ago. A century from now, they’ll still be around, but they’ll be unrecognizable.

The ways sneakers have already changed provide some clue as to what we can expect. Those milestones include the mass shift from buckles and buttons to laces for tighter and more variable fits, the move from Charles Goodyear’s vulcanized rubber for soles to industrial materials, and the installation of shock absorbers designed to limit harmful impacts on joints. Sneakers are getting more complicated year in, year out.

Yet, there are still plenty of ways to improve sneakers. Here’s what we can expect in both the short-term and long-term:

Laces

Remember Marty McFly’s Nike Mag sneakers in Back To The Future II? No? Stop reading this story and go watch the movie. Get some priorities.

Well, Nike finally released a limited edition Mag design to the public in 2011. But they were missing one key feature — power laces. Nike is planning to release a version of the Mags with power laces sometime this year — just as the movie predicted they would. It’s not so much life imitating art as life profiteering off of art, but we’ll take it.

While many people might decry that self-tying laces are just another sign of 21st century laziness, they are probably forgetting that plenty of people in the world are simply unable to tie their laces due to disabilities. On that note, Nike also spent that last few years developing the Flyease design, inspired by a letter the company received from Matthew Walzer, a college student with Cerebral Palsy. Walzer, like many others with physical limitations, has trouble tying his shoes. The Flyease design, which features a zip up the back, will go on sale in Soldier 8 form this Thursday.

Far in the future, however, we can probably expect most shoes to begin implementing either a self-tying feature or to completely jettison laces in favor of a different design that tightens and loosens. Untied sneakers don’t look crisp and poorly tied sneakers don’t provide adequate support.

Soles

Sneakers have been using rubber soles for over a century now. Almost all natural rubber comes from hevea rubber trees in Southeast Asia. This has shoemakers, tire-makers, and other rubber-heavy industries nervous that the slightest conflicts could result in devastating shortages.

Some Americans, however, are looking into using guayule plant products as an alternative for natural rubber. The material is just as durable and robust, but cheaper to produce and process for manufacturing purposes.

That’s not the only way soles are changing. Nike has been prototyping cleat soles made from 3D printers as a way to create more effective spike designs to enhance player speed and traction. This points to a future where specialized soles can be swapped out for the sake of performance.

Materials

We’ve already mentioned 3D printing, which eliminates the need to stitch and seam different parts together. Another technology Nike is looking into is vacuum compression, which therm-molds the upper body of the sneaker together so it’s a single part.

Some companies are also turning to older manufacturing technologies as a way to make new sneakers. Just take a look at Primeknit by Adidas, or Flyknit by Nike. As the names describe, the shoes are made from a machine that weaves a single piece of fused yarn into the shape of a cleat, or running shoe. It’s a much less labor-intensive and wasteful process to make shoes — and the resulting kicks actually look pretty awesome. Best of all, the yarn could be made from a whole slew of different materials, like carbon, wool, kevlar, nylon, or even metals like gold or steel.

Extreme Design

There are also just a ton of other experimental technologies making their way into sneakers now. It’s an exciting time see how new innovations are blowing up a product we take for granted every day.

UK company +rehabstudio is currently working on Shift Sneakers — a wearable technology in which phase-changing fibers and shape-memory materials can transform into different colors and designs based on input from a mobile app. It’s a conceptual technology, but it means you’d have a hundred different designs for the price of just one pair of sneakers.

Energy needs will be a big issue to tackle in the future, and some scientists are already thinking about how to harness shoes. University of Wisconsin-Madison engineers recently developed a shoe insert with microfluidic technology that converts motion into energy — capable of creating one kilowatt per 10.76 square feet. The stored power could then be used to charge devices, like a mobile phone that just ran out of juice. Next time you’re running around to find an outlet for your charger, you could just run as a way to power it yourself.

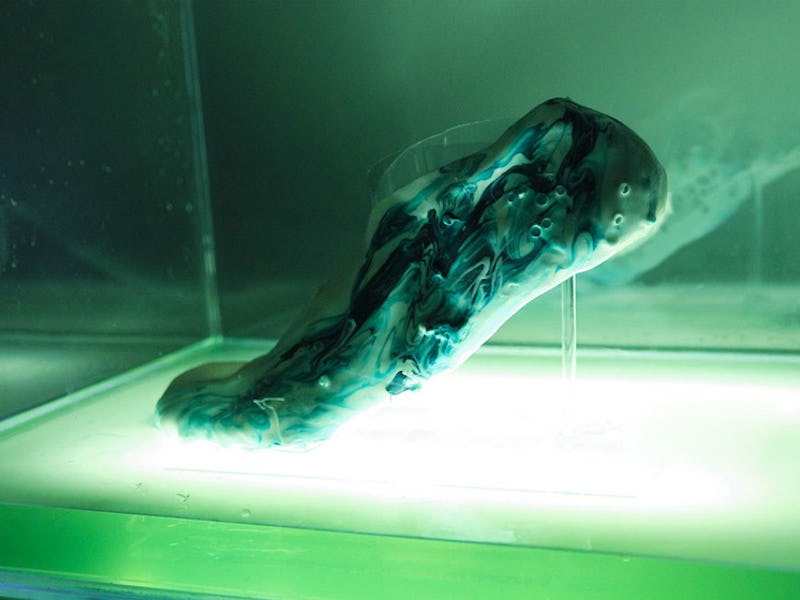

Perhaps the craziest design idea is to create self-repairing shoes through biological cells. UK designer and researcher Shamees Aden developed a concept for sneakers that could be 3D printed with synthetic biological material. These shoes would have the capability to repair themselves after sustaining any kind of wear and tear. The “Amoeba Trainers” are a totally far off idea, but with how rapidly synthetic biology tools are developing, it’s also not totally inconceivable this could be the future of shoes.