These "Printed" Solar Panels Were Made for Energy-Starved Regions

These panels are in the final testing phase before being released to the public.

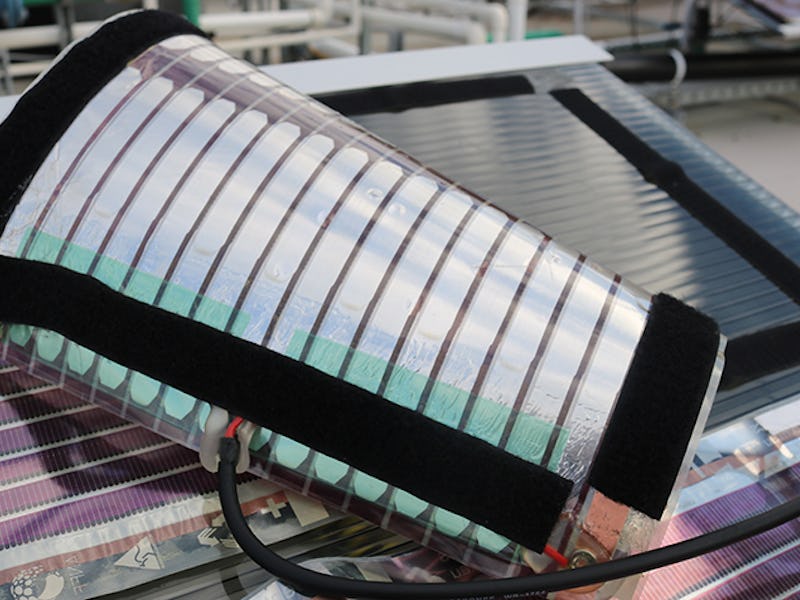

On Monday, a team of researchers in Australia unrolled a field of the first solar panels printed using a standard printer, solar ink, and thin, laminated plastic. And we mean literally unrolled: These solar panels are flexible enough to be rolled into a tube.

The panels are developed by Paul Dastoor and his team at the University of Newcastle, who have also created the solar ink and printing method over the last five years. The demonstration of the rollable solar panels covers an area of about 1,000 square feet, which Dastoor says is one of the largest solar tech demonstrations in the world in the announcement. Although the panels are not yet commercially available, this is one of the final tests before the rollable panels are released. And the $1 per square foot cost makes up for the fact they they’re not as pretty as a Tesla solar roof, particularly for the military.

To make the panels, Dastoor’s team puts a water-based electric ink into a printer cartridge and prints out the panels onto thin sheets of plastic. The solar ink is very sensitive and uses semiconducting molecules within the ink to catch energy from the sun and transfer it through the cell to a battery. Dastoor says he expects a commercial printer to be able to make kilometers worth of printed panels in a single day.

The exact rate of capture of solar power of the printed cells hasn’t been announced, but solar paint by Dastoor’s team converts about three percent of solar energy into power. Conventional solar panels can convert about 20 percent.

“This installation brings us closer than we have ever been to making this technology a reality. It will help to determine the lifespan of the material and provide half-hourly feedback on the performance of the system,” Dastoor says in the press announcement.

Despite the fact that it’s likely to produce less electricity than a more expensive Tesla solar tile, the panels have significant applications in military bases and disaster relief. The panels can be air-dropped into locations without fear of damage and are so light they have to be stuck down with velcro so they don’t blow away. With the ease of transport and low cost, they can easily bring electricity into areas that are cut off from infrastructure.