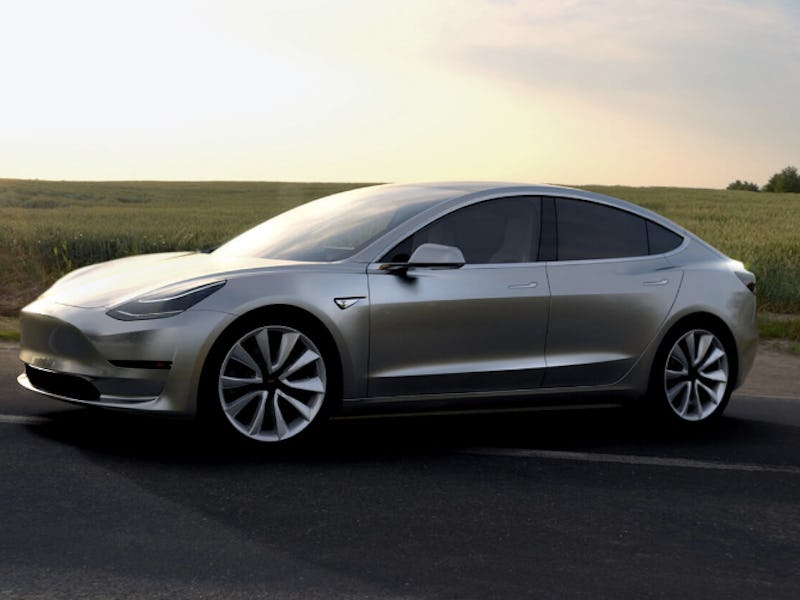

Tesla's "Impossible" Model 3 Production Date Is One Year Away

There's still a lot more that needs to be done.

On May 4 of this year, Elon Musk told Tesla investors and the world that the production date for the wildly popular Model 3 is July 1, 2017. Musk said that Tesla is holding its suppliers’ “feet to the fire,” to get everything going by then, but he also acknowledged one major problem: “July 1, 2017 is an impossible date.”

Musk isnt afraid of impossible deadlines, though. Fully autonomous cars are far from being regulated or even accepted by society, but that didnt stop Musk from predicting that half of the cars sold in seven or eight years will be fully autonomous. SpaceX has only made it into orbit, but Musk didn’t shy away from saying his rocket company could make it to Mars as early as 2018.

The clock is ticking a little louder for the Model 3 deadline, though. As of today, Musk only has one year before that “impossible” date. The Model 3 — the mass-market electric vehicle of Musk’s dreams is inching closer to reality. Tesla has hit some of its goals, but Musk and co still have a lot more to do to make their production deadline if he really wants to start shipping cars out by 2018.

Capital spending

In 2016’s Quarter 1 investor letter, Musk warned that Tesla will have to lose money in 2016 to fill the unprecedented number of Model 3 reservations.

Tesla sold more stock to offset the high price of Model 3 business, and by May 20, it had raised $1.46 billion from sales of the new shares. A large chunk of that money, around $1.26 billion, will be put toward expanding Tesla’s Fremont Factory to handle Model 3 production. Tesla will have to take on more debt to pay for everything else.

Of course, stocks change direction like a fart in a fan factory. And even though Musk has “zero doubt” that Tesla should acquire solar panel company SolarCity, it is a huge distraction for the company and isn’t helping Tesla’s stock price any.

Probably won't be out on time, but still red hot.

New hires

The Model X was plagued by poor production planning — the vehicle came out over a year later than expected, and early models were still a little rough when they first shipped. Both Tesla’s vice president of production and its vice president of manufacturing left the company right before Musk’s earnings conference call this May. Both execs were involved in the delayed Model X roll out, and both would have been partly responsible for getting the Model 3 out of the door.

During the May 4 call, Musk hinted at an exciting hire to come, and shortly after, Peter Hochholdinger, the previous senior director of production for the Audi A4, A5, and Q5 was named Tesla’s new vice president of vehicle production. Hochholdinger brings some much needed experience to a green company like Tesla.

Still, Hochholdinger’s appointment wasn’t without controversy. The Audi Q5 that was made while he was running the show was one of the vehicles involved in the Volkswagen (which owns Audi) emissions scandal — luckily, Hochholdinger won’t have to worry about pesky things like emissions at all-electric Tesla.

In-house production

The Model 3 is going to be affordable partly because Tesla is going to be making its own lithium-ion batteries. The key to their production is the Tesla Gigafactory outside of Reno, Nevada, which is also still under construction. The building is coming along well, but it takes a long time to build the building with the future largest footprint of any building in the world. Still, the first section of the Gigafactory is slated to open on July 29.

Tesla wants to move more of its production in-house so that it doesn’t have to rely on other providers. That would be great for getting things done, but manufacturing parts takes equipment that costs a lot of time and money to install. Tesla’s fine on cash, but with just a year left before Model 3s are supposed to start rolling out of the factory, it’s short on time.

Getting ready to hit the open road. Maybe.

Can Tesla do it?

Maybe. Possibly. Probably not. All of the above. The company has made some steps forward, but there are so many factors that go into production that it’s hard to see the Model 3 production line start one year to this day.

Musk said himself that cars are difficult because even if every part the car needs is supplied on time except for one, the car can’t be built.

“I’d be really surprised if he can launch production by next July,” Frank Faga, a Detroit-based auto manufacturing consultant, told Reuters in May. “But this is a guy who says he’s going to Mars. Who am I to say he can’t do this?”