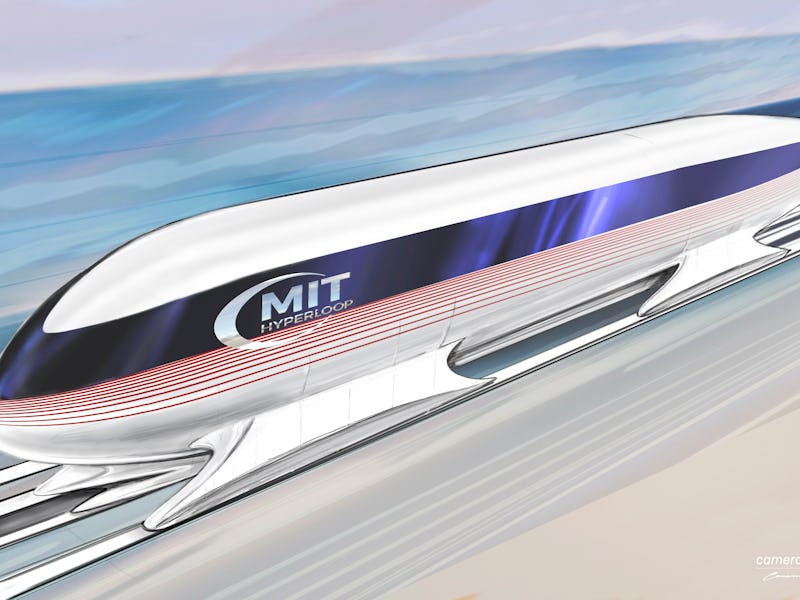

After Winning the Hyperloop Competition, MIT Looks Ahead: "We'll Be Sure to Impress"

"Now the whole world is going to be watching us."

John Mayo and his colleagues are stoked for what will be an intense next few months. “We’re getting off the high of doing well at design weekend, but now the whole world is going to be watching us.” He’s referring to his team’s sort-of-surprising, sort-of-not first place finish at the first leg of SpaceX’s Hyperloop Pod Competition last month in Texas. He’s also referring to the daunting task of building a working, human-scale Hyperloop pod capable of zooming around at speeds of up to 700 mph. They have until the summer to make it happen.

Mayo is the project manager for the Massachusetts Institute of Technology Hyperloop team, which took home top honors for the competition’s design weekend at Texas A&M in late January. MIT’s first-place finish was followed by Delft University of Technology of the Netherlands. The University of Wisconsin, Virginia Tech, and the University of California, Irvine rounded out the top five.

While MIT didn’t have it locked up — there were a ton of really compelling designs put forth by a ton of teams from institutions large and small — it was favored to win. But when you’re sponsored by the nation’s (and arguably the world’s) best engineering school, you’re expected to show up to these kinds of competitions as a leading contender.

This was just the first leg of the competition, its purpose to whittle down the incredibly big pool to just 10 teams. These final contenders will now build and put their pods into action at a one-mile, six-foot-diameter track in Hawthorne, California, this summer.

For now, MIT Hyperloop has emerged as the team to beat. And they did it with a design that didn’t even have room for a single person, or even cargo.

I know what you’re thinking — how the hell can you win a transportation design competition when your design can’t technically transport anything?

The point of the competition is to demonstrate the feasibility of getting something like Hyperloop to actually run — that you can have a pod move through a giant tube based just on air pressure and manage to get you from San Francisco to L.A. in 30 minutes.

With that in mind, the MIT team was aiming for the minimum standards that would let them prove the concept. While Musk’s original white paper pitched something that would move at 700 mph, the actual test for the competition just needs to go at 240 mph.

Mayo tells Inverse the team identified five parts most important to Hyperloop: levitation, braking, control, high speed acceleration, and telemetry. The team specifically chose to focus on the first three — so while the pod could very well hit a top speed of 700 mph, that’s not what its optimized for.

Mayo and his colleagues chose to make levitation possible through magnets, since SpaceX has veered away from the white paper concept of a smooth tube, to a tube with a concrete layer and aluminum plates on the bottom, and an aluminum rail on the top, with welds about a half-inch tall. Using the surface of tube, Mayo says, isn’t really viable anymore. The aluminum tracks make it possible to work with air bearings, but they also offer electrodynamic suspension via magnetic levitation.

“It uses no power,” says Mayo. “That actually works better than air bearings.”

The team was adamant about developing a braking system that could ensure safety at ultra-high speeds. “In an actual Hyperloop, you wouldn’t stop [the pod] at 2.4 Gs,” says Mayo. “But on the mile-long test track, without people, you need to after you get up to high speeds, to prove your levitation systems work correctly.”

Since the competition pod doesn’t hold people, the MIT team “chose to scale [the pod] down into something that we could build,” says Mayo. The team has to have it built by June and there is still plenty of testing to do. Figuring out how to have another passenger compartment is currently a bit less important than, say, creating the systems for braking and control.

One of the predominant ways MIT separated itself from the competition was the manufacturability of their creation. Every single part was carefully analyzed and scrutinized before the team decided to make it a permanent part of the design. These considerations might be at the cost of a more appealing and sleek look, but for Mayo and his teammates, that’s a small price to pay. “That’s not necessary to prove Hyperloop,” Mayo asserts.

But in other ways, MIT’s design was very similar to their competition — like in closely collaborating with business students the way teams like Carnegie Mellon University’s did.

In addition, a few private companies are helping to sponsor the team and provide financial investment. One of those companies, Magplane Technology, designs and fabricates pipeline transport systems used in current and planned transportation projects.

Still, the MIT team is primarily focused on the engineering and manufacturing of their prototype right now, for the final round of the competition.

Limitations to the team’s design do persist, though: The electrodynamic suspension system is not something that’s been very widely tested, so the team’s proposed levitation method is relatively new. Like the braking, the levitation system is designed for high speeds and is difficult to test at lower speeds. This will pose problems for how the team will test and troubleshoot the pod before the summer’s main event at the Space X competition (date and location TBA).

All eyes are on MIT at this point, and nobody knows this better than the team. “We know we have to go out and impress,” says Mayo. “But we’ll be sure to impress.”